Project duration: 4 April 2017 – 31 December 2018

Objective

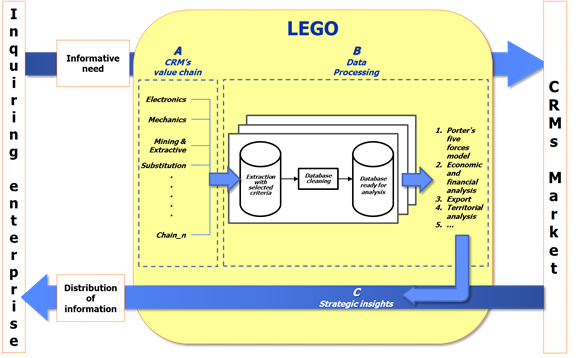

This project aims to lay the groundwork for an exchange network and export platform for innovative circular economy business model design, with internationalisation activities particularly focused on China. We will do so via integrating best knowledge and practices by the consortium, which brings together partners from EIT RawMaterials highly experienced on economic/environmental models (e.g. multi-regional metabolisms analytical tools and database), circular business design and governance innovation, and best regional implementation practices. Combining with our circular economy projects in China and already existing network with China’s stakeholders, we further aim to create an EU-China communication platform that can further enhance the collaboration on circular economy initiatives with a better understanding of circular economy business models.

Via the expertise of EIT RawMaterials, resource-efficiency and circularity give the potential of cost reductions in industry, which forms the basis for EIT RawMaterials to generate revenues. TNO estimate such cost reduction potential for the Netherlands at 7 billion Euro alone, and estimates at a global level range in the 100s of billions (Ellen MacArthur Foundation, 2012). China, being the biggest manufacturing economy globally, forms a major share of this. As indicated in the call, the 2016 call for internationalisation seeks explorative projects that identify opportunities. That is exactly what this project aims at. By gathering the strongest EIT RawMaterials partners and creating networks with Chinese counterparts, we are quite sure to get a good insight into the potential business opportunities for the EIT RawMaterials. These then can be worked out in concrete revenue generating business models and approaches in a follow-up internationalisation call that goes beyond inventory and exploration. Finally, with this consortium and network, we expect that we can already incubate follow-up projects both in EU and China paid by non-KIC sources, particularly since China is just in the beginning year of its 13th five-year economic development plan, we expect there are various opportunities for follow-up projects.

The solution (technology)

The whole network is expected to share knowledge and create business opportunities bilaterally so as to help circular economy practitioners to promote the optimal resource efficiency options. Based on the established intelligence network and communication with China’s partners, this project will promote synergies with the various actions that the EU Commission plans to implement with non-EU partners from 2015 onwards on raw materials, and provide an innovation agenda on future EU-China CEB collaboration, and bring business opportunities for EIT RawMaterials through enhancing circular economy in China’s local market. There is a genuine potential for creating business opportunities for KIC partners, by developing joint projects with Chinese partners that enhance resource efficiency and circularity and in this way reduce costs. With the collaboration of network, it is also expected to export EU and KIC’s products and business to Chinese circular economy market (software, databases, recycling technologies and products). From a financial sustainability perspective, the intelligence network constructed by this project and the knowledge contribution to innovative business model development for services with regard to circularity and resource-efficiency will, in the end, provide opportunities for EIT RawMaterials to create business value and revenues.

Partnership

- Leiden University, The Netherlands (Lead Partner)

- Fundación Tecnalia Research & Innovation, Spain

- Ghent University, Belgium

- Kungliga Tekniska Högskolan, KTH (Royal Institute of Technology), Sweden

- National Technical University of Athens, Greece

- Technische Universiteit Delft (Delft University of Technology), The Netherlands

- Université de Bordeaux, France